Categories

- Our Blog (69)

- Technology Support (18)

CNC machines short for “computer numerical control machines, are automated milling devices that make industrial components without direct human assistance.

There are many different types of CNC machines, but the most common ones are milling machines, lathes, and grinders.

However, the CNC machines are not only very expensive for each device, but also work every 7/24 hours in operation very easy to get a fire and the fire destroys them.

So that the workshop owners are always suffering from a great loss.

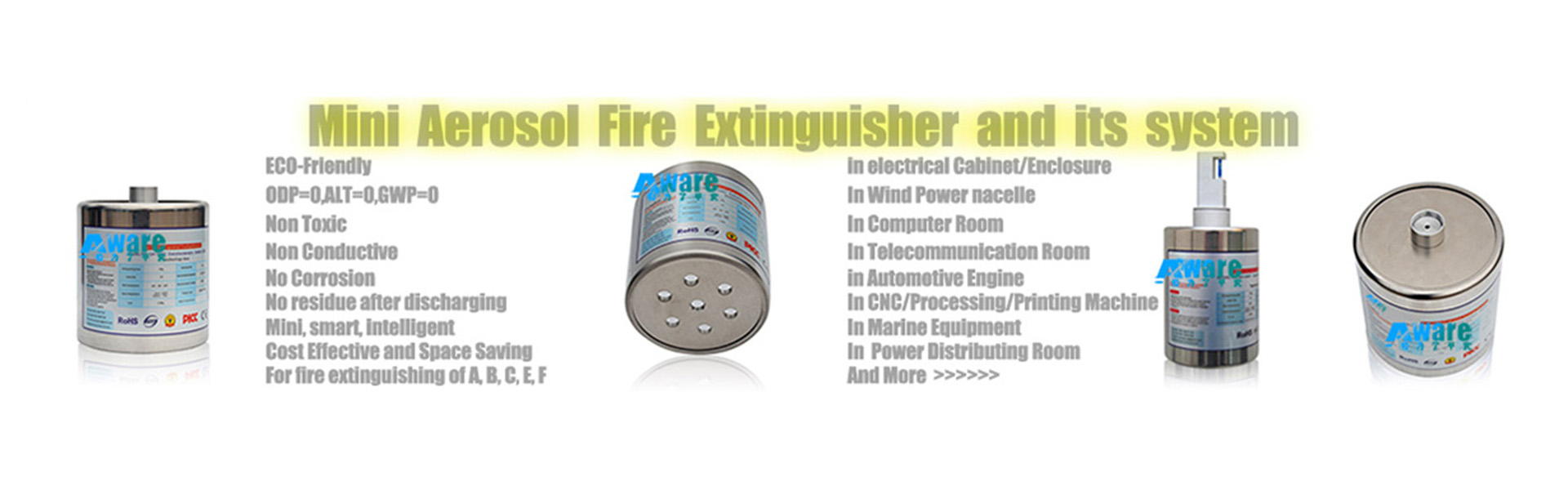

Now not only in China but also all over the world showing interest in installing a small size and highly effective fire suppression device inside the CNC machines, one kind of small size aerosol based fire extinguishing device because come into people’s sight.

Why do people like the fire extinguishing aerosol system device in CNC machines, we list out the following points:

In practice and after many actual tests it proven that the aerosol fire extinguishing system and its device are very suitable for installation in CNC machines.

Inside a CNC machine space, the temperature is always a bit high, and the working temperature of an aerosol fire extinguishing device is normally from -40 to +108 degrees Celsius, so an aerosol system is very suitable to install in a CNC machine space.

An Aerosol system is good to install in CNC machines, one method is to use an installation bracket and its screws to fix the aerosol inside the CNC machine space, it could be fixed on the top, or the side, another is to use magnetic and 3M glue to adhere it to the top ceiling or side of the CNC machines.

The Aerosol system works to flood the whole CNC machine spaces to suppress the fire, it runs out of the fog-alike aerosol compound and quickly reaches everywhere in the CNC machine spaces to extinguish the fire.

We kindly recommend thermal cord activation of the aerosol fire extinguishing device or thermo bulb activation of the aerosol fire suppression generator inside the CNC machine because using them does not require any fire alarm system to work with, and so easy to install.

Aerosol has the following basic specifications:

How we design fire extinguishing aerosol systems in a CNC machine room, hereby we list out an example below:

A compact center-less style internal grinder with a size of 690 mm in length, 670 mm in width, and 450 mm in height requires to design of a small fixed aerosol fire extinguishing device to protect.

Firstly, calculate the protection volume of the machine, it is 0.69m*0.67m*0.45m and comes to 0.20 cubic meters.

Secondly, to choose which quantity of aerosol and which model to install in this machine, we have already calculated out the protection volume is 0.2 cubic meters, so the required aerosol device can cover this volume, as our aerosol design density is 100 grams per cubic meter, and our smallest model is 30 gram of aerosol device, so Model Number AW-QH-30TH(or AW-QH-30ST) is needed to design and install in this grinder machine.

So you can see only a small capacity of the aerosol device can be installed inside the expensive grinder machine, so it is cost-effective and workable.

In China, we have installed many aerosol devices inside the CNC machines for many manufacturer companies and small workshops, and also in the overseas market we have many cases if readers of this article have some similar project which will require a fire suppression system to cover the CNC machines, then please feel free to let us knows, we would like to design and service for you.

Aerosol devices not only be able to installed in CNC machines but also can be able to used in some of the following similar spaces:

Some people do not like to install a small fire suppression device inside the CNC machine the reason is that the machines seldom catch fire or there is zero possibility of catching fire, in their real operation it is true seldom a fire in a CNC machine, but once a CNC gets a fire, then the whole workshop and their equipment and cargo will get destruction in even in one night.

In China in our city there is a block company that produces bus energy that caught fire in one workshop and caused a loss of USD1500000, the cause of the fire is that one milling machine operated for a long time and melted the electrical cable to catch fire, so consider of this are you still think it is not necessary to have a fire extinguishing device installed inside a CNC machines? This is a serious question we need to think about.